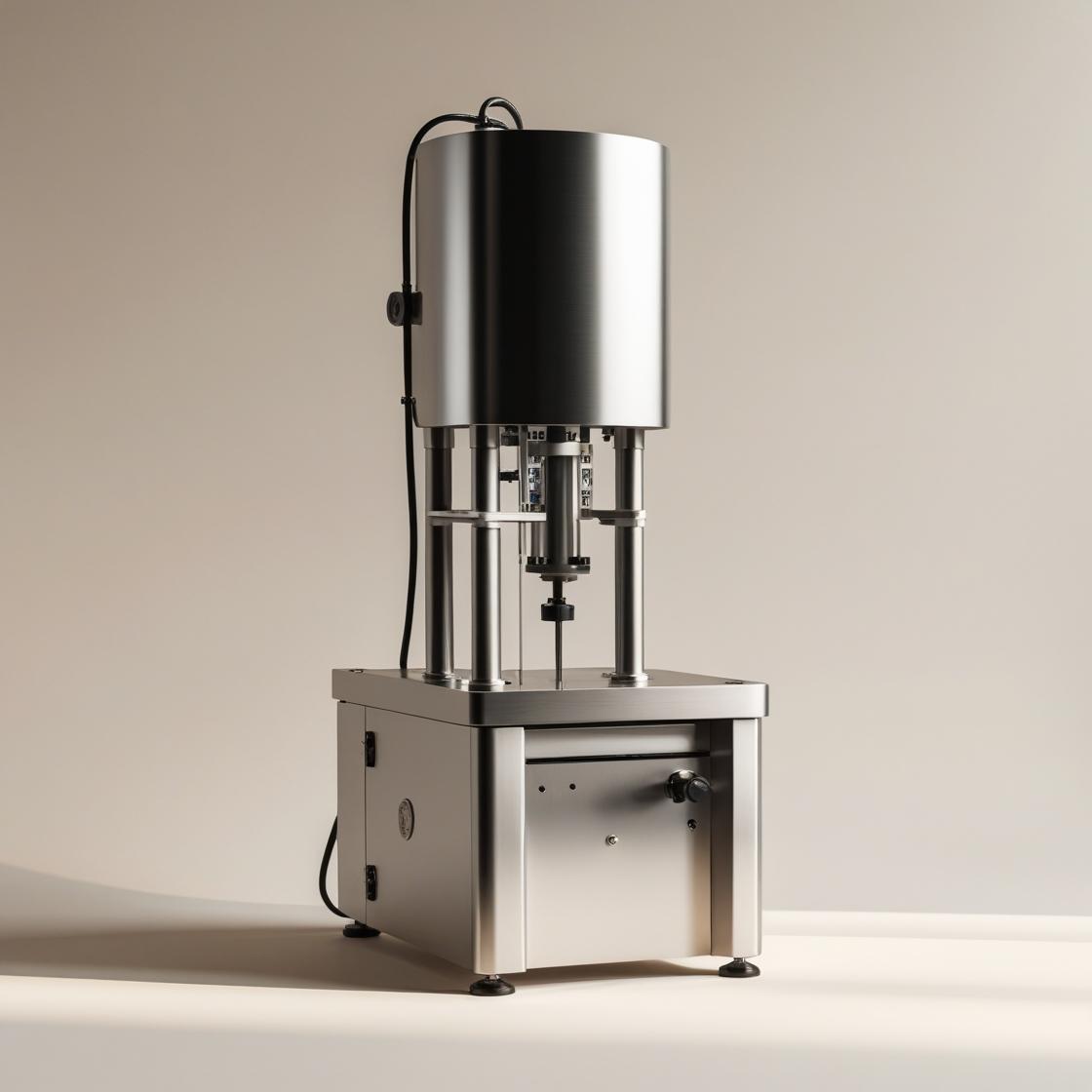

Automatic Tube Filling Sealing Machine

Automatic Tube Filling and Sealing Machine

Fast. Accurate. Hygienic. Made for High-Speed Production.

Amson Engineering presents a fully automatic tube filling and sealing machine, engineered for high-volume packaging of laminate, plastic, and aluminum tubes. Whether you're in pharmaceutical, cosmetic, food, or chemical sectors, this machine ensures precise product dosing, airtight sealing, and GMP-compliant construction—ideal for creams, gels, ointments, pastes, and lotions.

✅ Key Features:

-

PLC-controlled automatic operation with HMI touchscreen interface

-

Suitable for plastic, laminated & aluminum tubes

-

Filling range: 5 ml to 250 ml (customizable)

-

Output: Up to 60 tubes per minute

-

Hot air sealing, ultrasonic, or mechanical crimping (optional based on tube type)

-

Automatic tube orientation system with photocell sensor

-

No tube – No fill – No seal mechanism

-

Stainless steel 316L product contact parts

-

Batch coding, trimming, and ejection station

✅ Applications:

-

Pharmaceuticals: Ointments, antiseptic creams, medicated gels

-

Cosmetics & Personal Care: Face wash, creams, balms, lotions

-

Food Industry: Ketchup, mayonnaise, toothpaste, sauces

-

Chemical Products: Adhesives, sealants, lubricants

✅ Benefits:

-

High output with low rejection rate

-

Airtight sealing to maintain product shelf life

-

Compact footprint for space-saving installations

-

Hassle-free format changeover

-

GMP & CE compliant design

-

Operator-friendly controls and easy maintenance

✅ Why Choose Amson Engineering?

With a reputation built on precision engineering and client satisfaction, Amson Engineering offers customizable tube filling solutions for industries that demand efficiency, hygiene, and durability. Our machines are built to run non-stop, offering maximum uptime and ROI.