Dental Products Filling Machine

Amson Engineering is a trusted name in dental filling technology, offering a comprehensive range of Dental Products Filling Machines designed for accuracy, hygiene, and ease of use. Our machines cater to the specialized needs of dental laboratories, manufacturers, and research facilities, ensuring contamination-free and precise filling of materials like dental composites, EDTA gels, impression materials, and dual-part resins.

Built with GMP-compliant stainless steel contact parts and engineered for minimal wastage, these machines are available in manual, semi-automatic, pneumatic, and hydraulic models to suit all production scales.

Key Types of Dental Filling Machines We Offer:

-

Single Head Dental Composite Extrusion Filling Machine – For accurate extrusion of high-viscosity composites

-

Hydraulic Single Head Dental Composite Filling Machine – Ideal for pressure-controlled, high-density filling

-

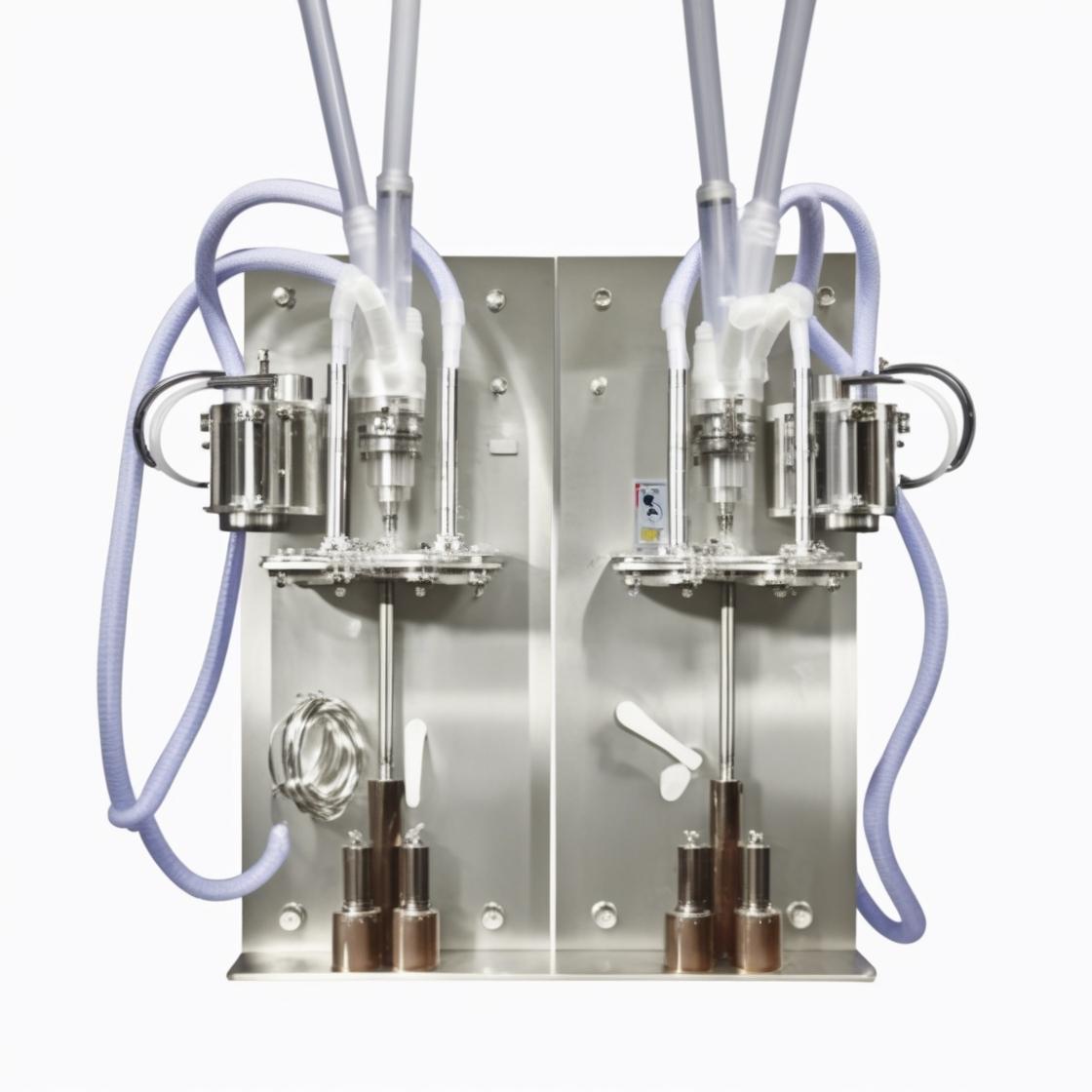

Hydraulic Multiple Nozzle Hard Composite Filling Machine – For bulk production with multiple fills per cycle

-

Dual Part Dental Cartridge Filling Machine – For 1:1, 2:1, or custom ratio materials

-

Single & Double Head EDTA Gel Filling Machines – For consistent dosing of endodontic gels

-

Hard Composite Extrusion Filling Machine – For specialized dense dental materials

Applications:

-

Restorative dentistry – composites, adhesives

-

Endodontics – EDTA gel, lubricants

-

Prosthodontics – impression materials

-

Orthodontics – bonding agents, adhesives

-

Dental Lab Production – bulk packaging for clinics & hospitals

Features & Benefits:

✅ Precision volumetric or servo-controlled dosing

✅ Air-free & bubble-free filling for superior product quality

✅ Contact parts in SS316L for compliance & durability

✅ Customizable nozzle designs for material type

✅ Available in manual to fully automated systems

✅ Optional heating, stirring & vacuum mixing hoppers

Why Choose Amson Engineering for Dental Filling?

With over two decades of experience in specialized filling technology, we understand the unique rheology and handling needs of dental materials. Each machine is engineered for smooth operation, consistent output, and regulatory compliance, making us a preferred partner for both domestic and international dental manufacturers.